Need Help or Have Questions

Order online

PRODUCT CENTER

- Stone Crushing Plant

- Sand Making Machine

- Stone Grinding Plant

- Ore Beneficiation Plant

- Production line

Hot Products

- Jaw Crusher

- Hammer Crusher

- Impact Crusher

- Cone Crusher

- Combination Crusher

- Stone Jaw Crusher

- Mobile Crushing Station

- Sand Maker

- Sand Washer

- Circular Vibrating Screen

Contact Us

- E-mail: sales@hxjq.com

- MSN: hxjq@hxjq.cn

- Tel: 0086-371-67833161

- Yahoo: hongxingmachinery@yahoo.com

The Crushing and Screening Process in the Ore Beneficiation

The crushing and screening work is necessary in the ore beneficiation process, and crushing refers to the process in which the small-sized particles are crushed into powder materials under external forces, and screening means the process in which the particles with different sizes are separated into different particle grade through the single-layer or multi-layer screening face.

The crushing and screening process is a crushing procedure composed by crushing and screening equipment. At present, the crushing and screening process has two-stage open circuit, two-stage closed circuit and three-stage open circuit, and every circuit has its own advantages and disadvantages. Next, the experts of Hongxing Machinery will give a detailed introduction to the typical crushing and screening process.

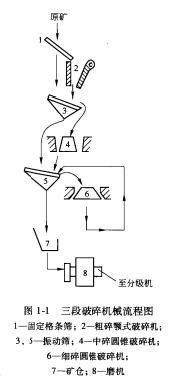

The detailed process is as follows: The raw ores go into the bar screen for preliminary screening in order to separate the fine particles in the raw ores, thus reducing the workload of the crushing machine. The materials on the screen go into jaw crusher, after being crushed, the materials will fall together with the raw ores onto the vibrating screen. Then the screened materials will go into the medium-crushing cone crusher. The materials crushed by the cone crusher will also fall onto the vibrating screen for screening. Then after being screened, the materials will go into the fine cone crusher. In this way, the vibrating screen is not only the preliminary screen, but the examination screen. The unqualified materials will go back to the fine crusher and the qualified products will fall on the material cabin and then be sent to the ball mill to become final products.

During this process, the fine crusher is closed circuit crushing, and the coarse crushing and medium crushing are open circuit crushing. The coarse crushing machine is generally one-stage crushing, and medium crusher is two-stage crushing, and the fine crusher is three-stage crushing.